Fastener Metrology - Securing Our Industrial Base

Fasteners may be small, but they are absolutely vital to the strength and success of our industrial base. Every product that moves, lifts, connects, or protects relies on fasteners engineered to perform flawlessly—because even the most advanced designs are only as strong as the components that hold them together. That’s why world-class metrology and uncompromising quality control are more than support functions; they are strategic advantages. By delivering precise, reliable measurement and verification in production, metrology empowers manufacturers to elevate performance, reduce risk, and build the kind of long-term trust that defines industry leaders.

Standardization in Fastener Production

The mass production of fasteners began in the UK in the mid 19th century with the invention of Henry Maudslay's lathe, which also happened to be the birth of the precision machine tool industry. This led to the creation of the British Standard Whitworth (BSW) in 1841, the world’s first standardized screw thread, which laid the foundation for interchangeable fasteners. In the United St, ASME and ANSI advanced this work with Unified Thread Standards (UTS), defining UNC, UNF, and UNEF thread forms that became essential across North American industries. Germany’s DIN standards introduced rigorous dimensional and material specifications that influenced mechanical engineering worldwide, while Japan’s JIS standards harmonized fastener requirements for the rapidly growing post-war manufacturing sector. Today, the International Organization for Standardization (ISO) plays a unifying role, integrating and aligning these regional systems into globally accepted specifications such as ISO metric threads (ISO 68, ISO 965) and performance classes (ISO 898).

FormTracer Avant H4D4000 - The Complete Machine for Fastener Production

The FormTracer Avant H4D4000 can enhance your quality assurance by giving you the right data needed to evaluate during the qualification process with speed and precision. Take all of your essential fastener measurements in one trace. With the dual sided stylus, you can create a continuous trace (top and bottom) to take multiple measurements at once. Surpassing the speed and accuracy of hand tools.

Best-In-Class Accuracy

FormTracer Avant H4D4000 delivers up to 0.08 micron accuracy um

Best-In-Class Drive Speed

80 MM/S Max X - Axis Drive Speed

30 MM/S Max Z2 - Axis Drive Speed

Dual Sided Stylus Offers Upper/Lower Continuous Measurements

Establish a complete profile trace with a continuous upper and lower trace. Giving you every critical measurement needed for a pass/fail check in one trace.

Form Tracer Avant H4D4000 Fastener Demo

Figure 1. FormTracer Avant H4D4000 with Screw

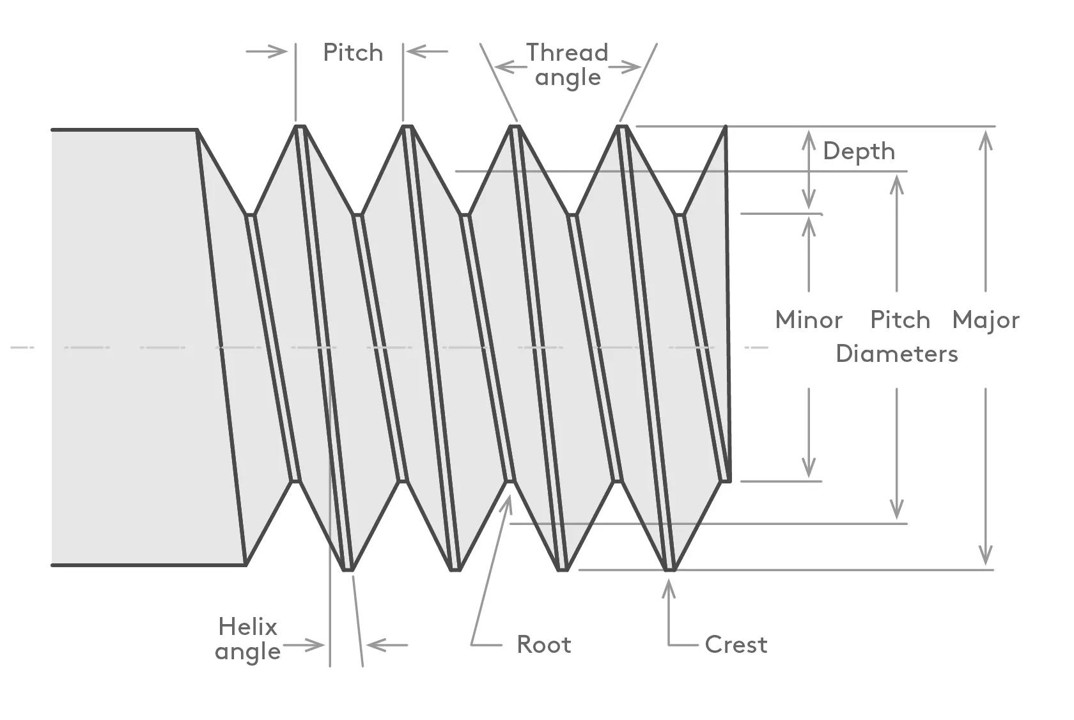

Standard Fastener Measurements

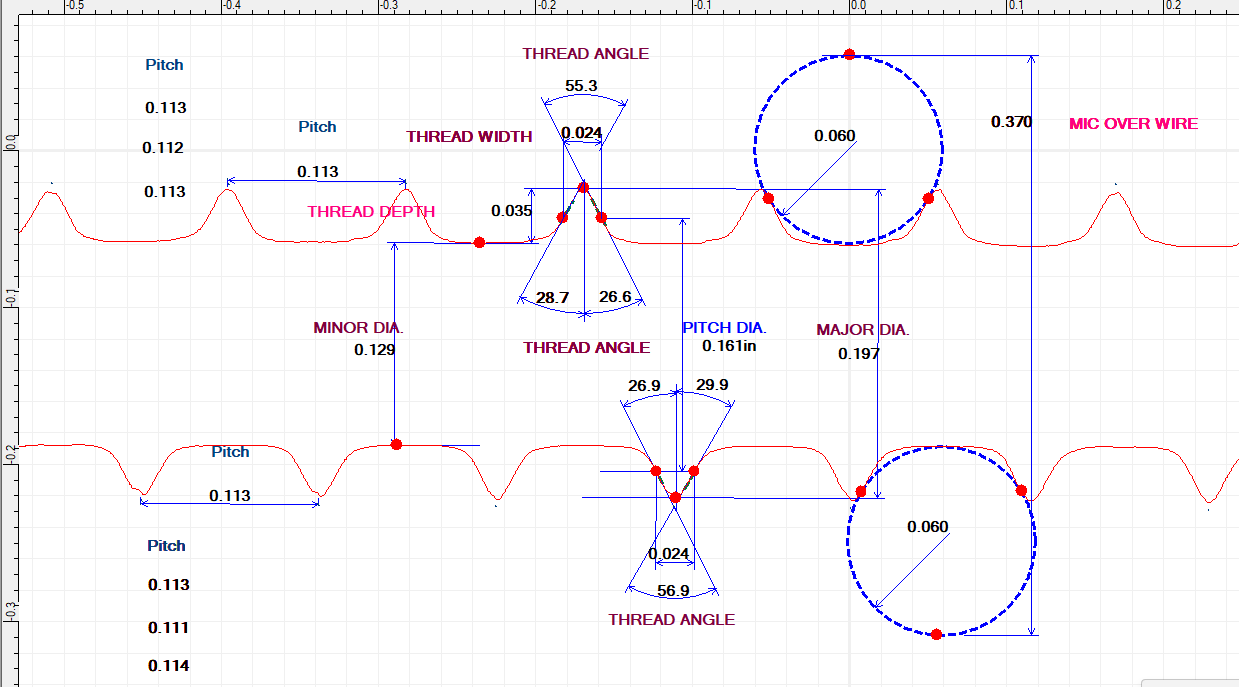

FormTracer Avant H4D4000 Demo Results

Results from Measurements Taken in Figure 1 Above

Manage All of Your Data In Real-Time with Measurlink

Make your production smart enabled with the implementation of Measurlink into your Quality Management program.

- Measurlink works in real-time. From charting cycles to identifying trends and fluctuations in your production, you can maximize efficiency through your quality control data.

- Part conformance visualization using real-time data prevents defects and enables metrics for process improvement capabilities.

Would you like to talk to an expert about your quality assurance program?

Related Solutions and Applications

MiSTAR 555 - Shop-Floor Type CNC Coordinate Measuring Machine

The MiSTAR 555 is a compact, shop-floor CNC coordinate measuring machine that ensures high-accuracy performance in challenging environments, including oil mist, with a wide, accuracy-guaranteed temperature range.

MACH-V - CNC Coordinate Measuring Machine for In-line Use

The MACH-V is a high-speed in-line CNC coordinate measuring machine that replaces dedicated gauges in production lines, providing flexible, maintenance-friendly operation and precise quantitative evaluations to enhance efficiency.

© 2025 Mitutoyo America Corporation. All rights reserved.