Solution Proposal from Mitutoyo

Precision in Every Plank: How Metrology Elevates Hardwood Flooring Manufacturing

Solution Proposal from Mitutoyo

Precision in Every Plank: How Metrology Elevates Hardwood Flooring Manufacturing

In hardwood flooring manufacturing, precise profile measurements—especially for tongue-and-groove joints—are essential to ensuring a flawless final product. These interlocking profiles determine how individual boards fit together, affecting not only the floor’s appearance but also its structural integrity and long-term performance. Even slight deviations in tongue thickness, groove depth, or alignment can result in gaps, squeaks, or instability once installed.

Maintaining exacting measurement standards throughout production, manufacturers can guarantee a seamless fit, smooth surface, and durable connection. Keeping up with the exacting measurements can be challenging, often creating excess scraps and costly down production time.

Measurement Challenge: Using Profile Measurements to Maintain Quality Assurance of Board Cuts

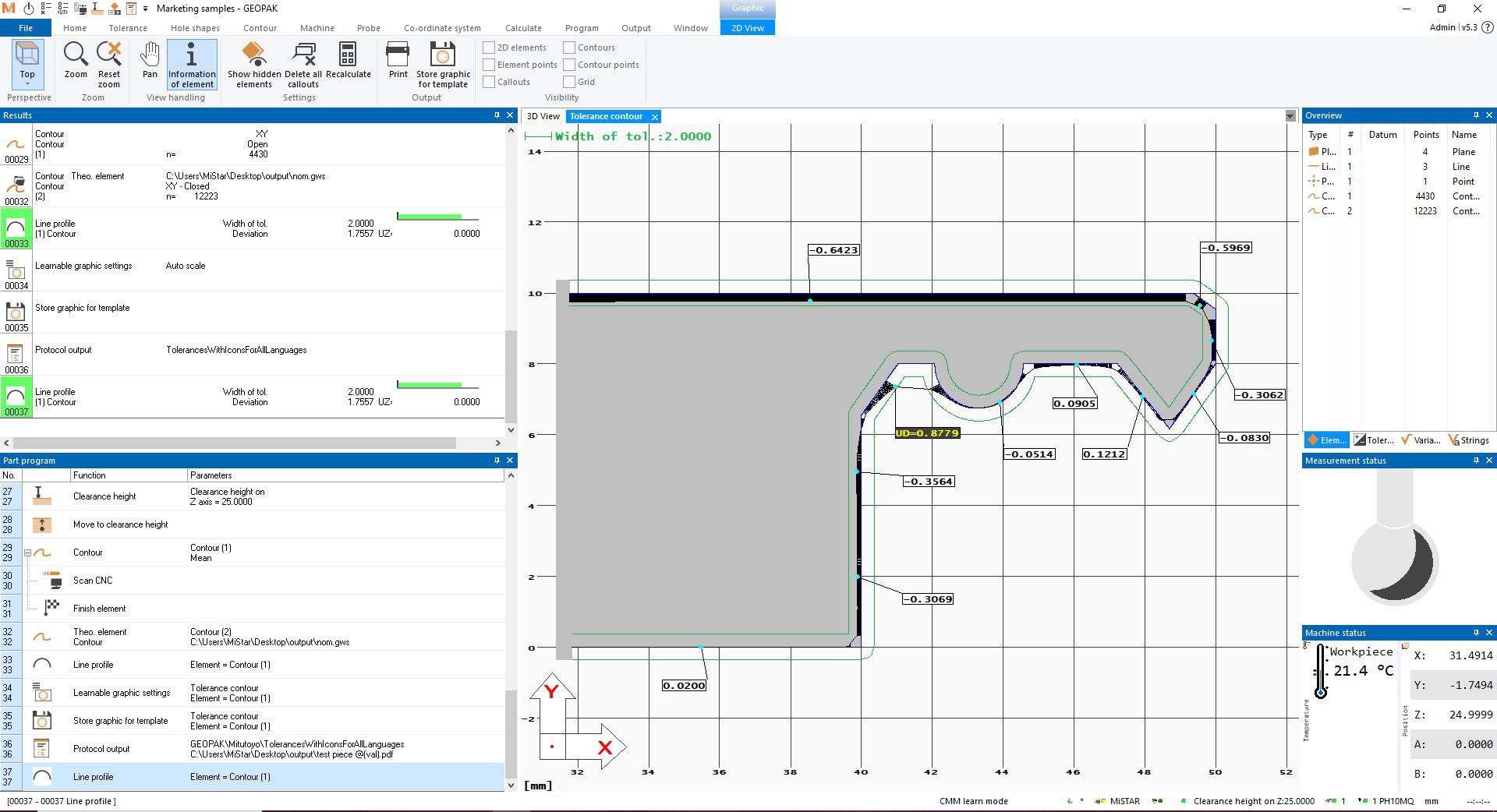

Mitutoyo’s MiStar 555 offers the measurement accuracy and ability to develop an easy-to-use profile measurement to quickly assess each board. This is needed for the start-up of production, changing product lines, or making adjustments mid-production to ensure quality assurance of each batch. With an accurate profile measurement the operator is able to adjust the cutting heads accordingly to maintain tolerances.

MiSTAR 555 Performing Tongue and Groove Profile Measurement

Profile Measurement Report

MiStar 555 Has Intuitive Features to Create Part Programs, and Keep Your Measurements Connected

Ease of Use with Quicklauncher

Operators can make easy measurements with the Quicklauncher touch interface for easy part program execution.

Profile measurement part program created with Quicklauncher

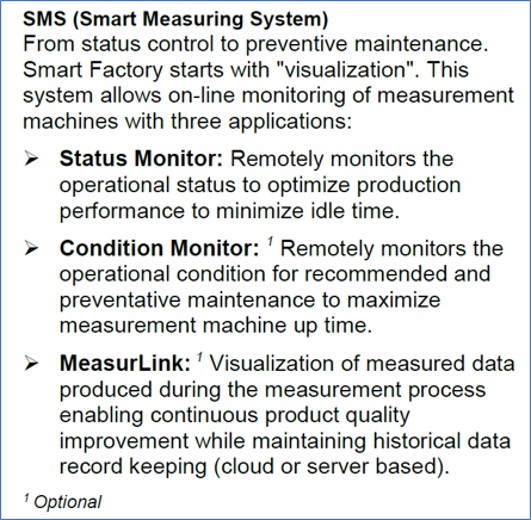

Keep Your Quality Assurance Optimized with the Smart Measuring System

Mitutoyo’s machines are smart enabled to keep your production line running smoothly (Status Monitor), make sure your machine is operating properly (Condition Monitor), and provide real-time acquisition/analysis of measurement data for continuous improvement (Measurlink).

Production Floor Example Utilizing Measurlink to Optimize Quality Assurance

Want to talk with a representative about how MiSTAR 555 can improve your quality assurance?

Related Solutions and Applications

MiSTAR 555 - Shop-Floor Type CNC Coordinate Measuring Machine

The MiSTAR 555 is a compact, shop-floor CNC coordinate measuring machine that ensures high-accuracy performance in challenging environments, including oil mist, with a wide, accuracy-guaranteed temperature range.

MACH-V - CNC Coordinate Measuring Machine for In-line Use

The MACH-V is a high-speed in-line CNC coordinate measuring machine that replaces dedicated gauges in production lines, providing flexible, maintenance-friendly operation and precise quantitative evaluations to enhance efficiency.

© 2025 Mitutoyo America Corporation. All rights reserved.