Bearing Casing Measurements with the FormTracer Avant H4H3000 and Roundtest RA-2200

In bearing manufacturing, the accuracy of the casing directly determines reliability, fit, and service life. Even minor deviations in contour or surface finish can lead to premature failure or costly assembly issues. The bearing casing plays a critical role in maintaining alignment, load distribution, and long-term durability. While bearings themselves are precision components, their performance depends heavily on the dimensional accuracy and surface condition of the housing they sit in.

Even minor deviations in roundness, coaxiality, or surface finish can lead to:

- Uneven load distribution, increasing wear

- Misalignment, causing vibration and noise

- Premature bearing failure, leading to costly downtime

Precision Perfected: Why Mitutoyo’s FormTracer Avant and RA-2200 Are the Ultimate Solution for Bearing Measurements

Mitutoyo’s FormTracer Avant (FTA) and Roundtest RA-2200 provide the precision and reliability needed to meet the highest standards. The FTA excels in capturing complex surface profiles, waviness and roughness, while the Roundtest system delivers ultra-accurate roundness and cylindricity measurements. Together, they form a comprehensive quality assurance solution, enabling manufacturers to detect imperfections early, maintain strict tolerances, and guarantee that every bearing performs flawlessly in its intended application.

FormTracer Avant H4H3000

Surface Roughness and Contour in One Trace

- Traditionally, measuring surface roughness and contour requires two separate devices or drive units. The FTA H4H3000 enables both measurements in just one instrument, significantly reducing user error and maximizing productivity. Designed for ball bearing manufacturers who need high efficiency without sacrificing precision.

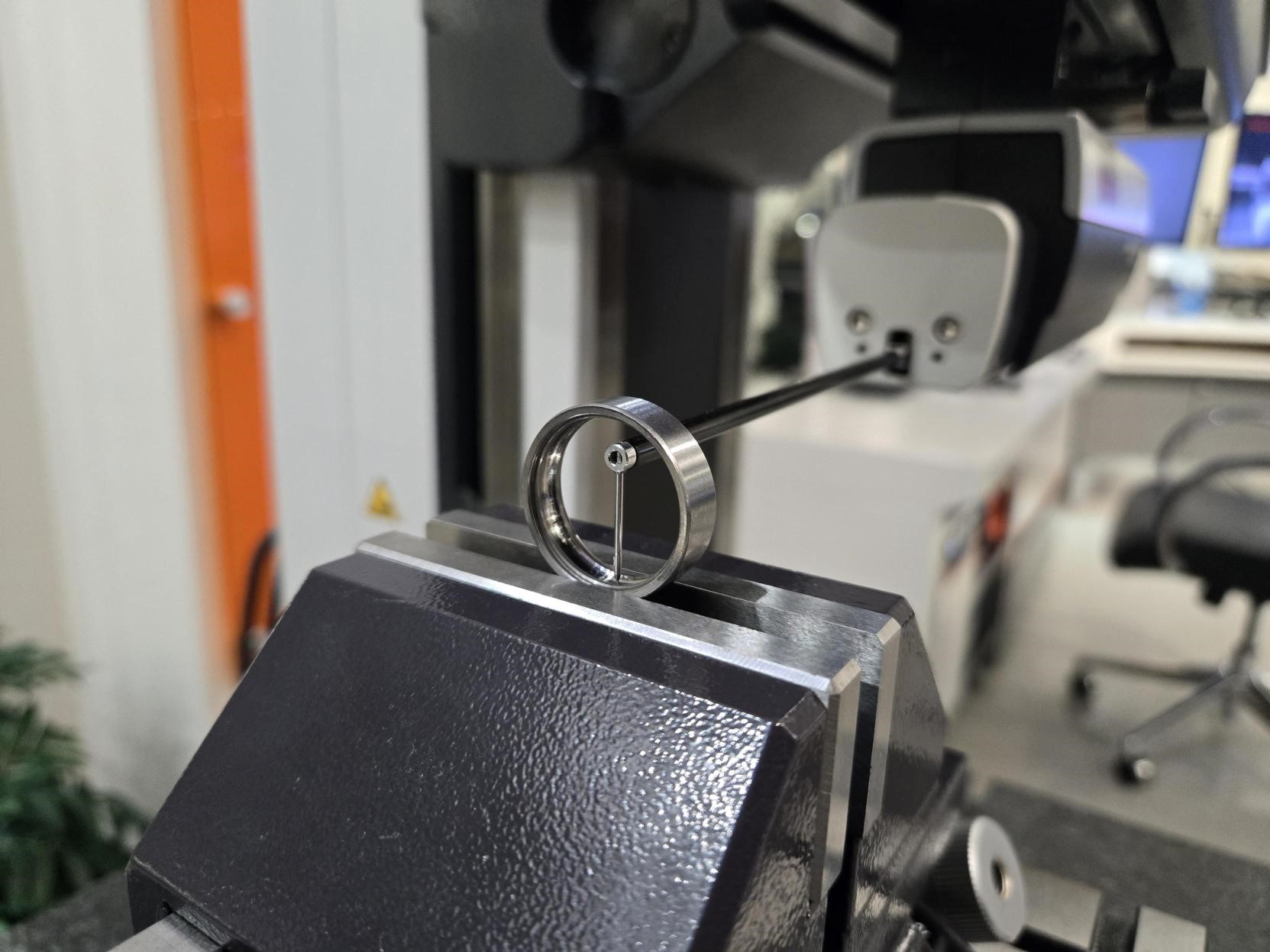

Figure 1. Ball Bearing Casing

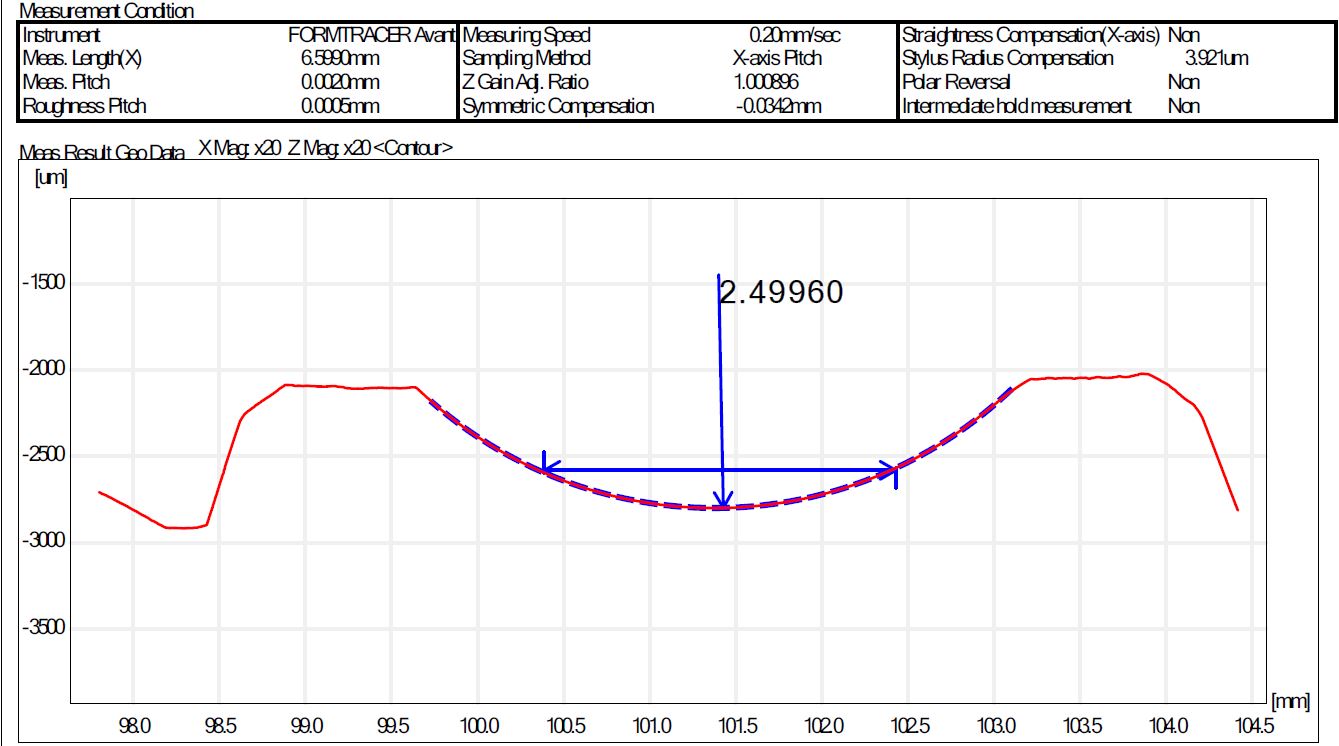

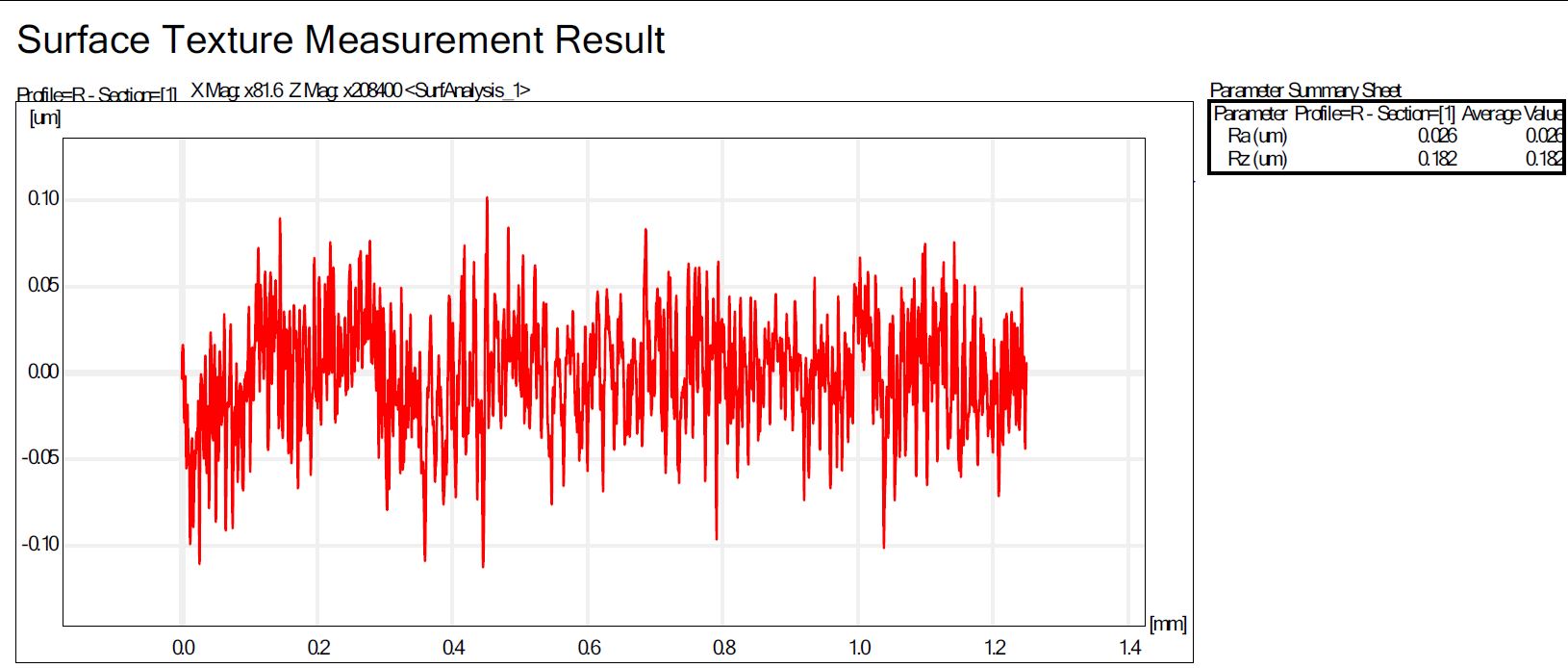

Contour Analysis on Figure 1

Surface Roughness Analysis on Figure 1

Best Accuracy with the Highest Range

- In measuring bearings, speed and accuracy are essential for running an efficient operation. The FTA H4H3000 has an industry leading 0.5+0.02H μm accuracy and a range of 16 mm.

Handshaking Ability

- Working with our custom solutions team the FTA H4H3000 can integrate into you in-line solutions with the Form EIO package.

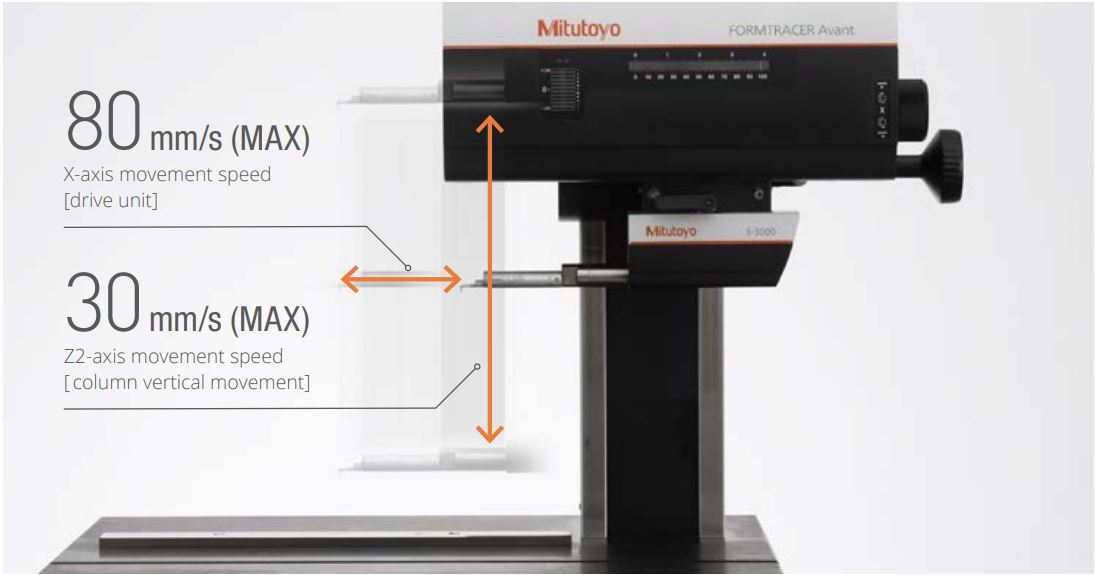

High Drive Speed

- The FTA H4H3000 has a high drive speed to move the detector head with speed to make measurements quickly from part to part.

Roundtest RA-2200

The cylindricity of the casing is critical to the overall function of the bearings. This essential part comes down to precision machining which can present various factors when defects occur. The Roundtest RA-2200 can not only diagnose defects on the part but also identify and correct machining issues before assembly.

Circularity Precision

-

Measure circularity of the casing with an accuracy of approximately 20 nanometers, which comes from the precise manufacturing of the spindle design.

Harmonic Tolerance Verification

-

Control your machining process accurately using harmonic analysis. Often times we measure quality assurance from the workpiece itself but with the Roundtest RA-2200 you can measure the machine’s frequencies exhibited on your part to determine errors in the machining process before they start.

Harmonic Analysis of Figure 1

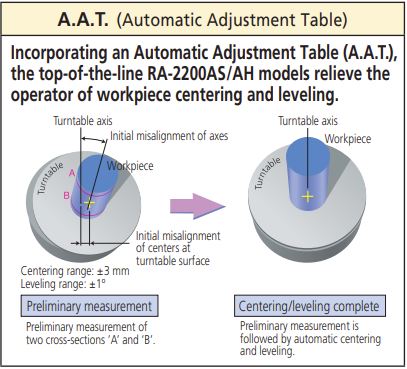

Automated Workpiece Tabling

To create efficiency with your measurements, the automatic adjustment table takes the tweaking of knobs out in centering and leveling the table to speed up measurements overall.

Want to talk to a metrology expert about your quality assurance?

Related Solutions and Applications

FORMTRACER Avant Series - Surface Roughness and Contour Measuring Instrument

The FORMTRACER Avant series offers versatile models that simplify setup and alignment, reduce workpiece securing time, and allow seamless conversion between contour and surface roughness measurement by retrofitting detectors after installation, ensuring precise measurements even in narrow areas.

RA-2200 Series - Roundness Measuring System

The RA-2200, our best-selling roundness measuring machine, offers exceptional performance and reliability with powerful centering and leveling support functions for precise and efficient setup.

© 2025 Mitutoyo America Corporation. All rights reserved.